http://michaelosullivan.com/ Overview http://midequalitygroup.co.uk/event/equal-midlothian-week-online-2021/?ical=1 :

The current trends in architecture and interior design are seeing a revival in the usage of organic materials, like clay bricks. Clay is on its way to become of the most sturdy, organic and preferred building materials for all types of green buildings – whether commercial, government or residential. It is loaded with other top-notch features, which make it the first and foremost choice for architects who want to create a positive impact with their green buildings.

Clay is one of the most sustainable design materials due to the following features:

- Energy efficient material

- Improved Facades at Lower Cost

- Thermal superiority

- Life cycle Cost Analysis

- Water cost-effectiveness

- Durability& Sturdiness

- Efficient &Effective Usage of Raw Materials

- Superior Acoustics

- BetterIndoor Air Quality

- Renewable & Re-usable materials

- Environmentally Preferable Materials and Products

- Safety and Security

- Good Structural Element

https://homoeopathie-nes.de/704-dtde46858-gay-dating-websites-in-australia.html Lifecycle http://weareconcert.com/news/bruceshaw-appoint-ian-hobbs/ :

Clay is one of the few organic materials, which not only contribute to green buildings but also ensure that there is zero wastage of the raw material at all. A typical Clay brick undergoes an interesting life-cycle in which it is able to end up exactly where it started from.

There are typically four phases in the overall lifecycle of almost any kind of organic clay product:

1. Mining of Raw Materials

The initial phase is a two-step process. Here, all the raw materials, which are required for the manufacture of the clay products are mined from the ground and then transported to the manufacturing unit.

2. Manufacture of the Building Material

During the second phase of the lifecycle, there are three stages. In the first stage, the actual product in manufactured from the raw materials. Any sub-standard product is re-cycled back to the raw materials during the second stage so as to ensure zero wastage of raw materials. During the third and final stage, the final product is transported across to the retailers, distributors and the eventual consumers.

3.Usage of the Material

The manufactured materials are used and they interact with the actual environment in this stage. The durability and the sturdiness of the manufacturing process is tested during its tenure of actual usage.

4. Re-Use on Reaching End of Life

At the end of the life of the product, it is recycled back as the raw material for other products or used for landscaping purposes.

Cost and environment impact and why it is preferred over other materials:

Clay has been one of the oldest building materials as it has been around for a few centuries. The manufacturing processes have also evolved over the years, which have reduced wastage and toxic environmental impacts whereas enhanced the quality of the final product.

The technological strides in the latest manufacturing units have managed to reduce the amount of water, energy and other resources needed to produce the bricks. Numerous programs and techniques adapted at the manufacturing units have ensured that waste and emissions are absolutely minimised, which definitely have a positive effect on the environment.

Clay bricks are one of the most preferred building materials over glass and steel as not only they are sustainable but also comply with numerous government rating standards as well, for green buildings. Glass and Steel have their constraints when compared to clay. They are prone to heat, weather elements, rust, increased energy consumption, non-fire resistant properties, low composite strength and high maintenance.

How it contributes to green building:

Clay is one of the best environment-friendly building materials and is the first and foremost choice for green buildings.

a. Better Air Quality

Clay bricks provide much better air quality in buildings because they do not use any kind of volatile organic compounds, which influence the air in any way. The indoor air is of enhanced quality as almost all kinds of volatile organic compounds are avoided. Clay bricks are manufactured in such a way that they do not succumb to mold as well, which also helps in enhancing the quality of air drastically. Clay bricks do not encourage mold formation in any form, even when they are dry or wet and hence are a great alternative for green buildings. On the other hand, any other kind of wall material can be attacked by mold especially in wet climates, which not only deteriorates the air quality but also lands up huge maintenance costs.

b. Superior Acoustics:

Apart from reducing air pollution, clay bricks are also an excellent in drastically decreasing the noise pollution as well. They have a good resistance to all types of sound penetration and boast of an STC (Sound Transmission Class) of more than 40. Hence, the indoor environment in green buildings made with clay bricks have a good level of acoustic comfort compared to other building materials.

c. Zero Wastage of Raw Materials:

Clay bricks are made from clay and shales, which are naturally found in abundance near the manufacturing units. This also reduces transportation costs of the raw materials, which in turn affects the overall costs and the environment. Also, almost all the raw materials, which is mined for the clay bricks ends up being used in some form or the other. Whatever percentage of processed materials – clay and shale are not eventually used up end back in the production unit. All the low quality bricks, which do not meet the exacting standards are culled and re-used up again in the manufacturing process or for landscaping purposes.

All in all, there is absolute zero wastage of raw materials in the manufacture of clay bricks, which impacts the environment and the green buildings in a positive and big way.

4. Durability:

Clay bricks are very durable and can effectively last for decades on end, with very little maintenance. What’s more, they are made from organic materials in a modern manufacturing plant, which optimises the resources and the energy used during the manufacturing process. Also, thermal efficiency is one of the factors involved in green buildings, which leads to reduced air-conditioning and heating costs.

Conclusion:

Green buildings are not just about creating durable and sustainable high-performance buildings that not only help the environment but are also on the track to last for the future generations and serve their needs as well. Architects plan, design and execute the green buildings in such a way that all the locally available resources are utilised in an effective and efficient manner. A well-planned, designed and executed green building is one that will balance all the economic, societal and the environmental aspects without compromising on the functionality, security and safety aspects.

____

Authored by a building expert from Wienerberger India

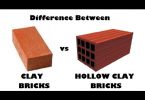

Wall Solutions – Benefits of #Wienerberger #Porotherm Clay Hollow Blocks