What is Fly Ash? It is a powder containing toxic metals like mercury, arsenic, antinomy, chromium, etc. These metals create a very negative impact on our environment and are one of the things that go into the making of Fly Ash Bricks.

In this blog, we shall highlight the 7 major disadvantages of using Fly Ash Bricks in your construction project.

Let’s Begin With – What Is Fly Ash Bricks?

Fly Ash Bricks is a building material made using class C or class F fly ash and water. Fly ash is a byproduct from coal-fired power plants that are frequently used as an admixture in concrete to replace a portion of the Portland cement.

Read : Top 7 Types Of Bricks Used In Indian Construction

Disadvantages Of Using Fly Ash Bricks

Image by Thamizhpparithi Maari under CC BY-SA 3.0

Fly ash in concrete is believed to improve performance in some ways, however, it has some evident disadvantages. We’ve highlighted a few disadvantages of using Fly Ash in concrete below:

1. Slow Strength Gain

Once concrete changes to a solid state a few hours after pouring, but its curing process takes longer. After its initial setting period, It continues to gain strength for weeks. The addition of fly ash can increase the length of time concrete takes to reach its full strength, this can be a big issue as slow strength gain directly affects the speed of construction.

2. Longer Setting Times

Fly ash admixtures can increase the time concrete takes for settling. Occasionally this could be desirable, mostly in hot weather where concrete set times are hustled, but during other times it can be a matter of inconvenience as it can delay construction. In such scenarios, other admixtures could be needed to adjust the set time of the concrete. Again, this proportion of admixtures could depend on the percent fly ash in the mixture and the outside temperature.

3. Poor Air Content Control

Concrete is vulnerable to damage from freeze/thaw cycles if it does not contain air. Here, tiny air bubbles can be created in concrete by using air-entraining admixtures which cause the concrete to foam in the mixing and pouring stage. Fly ash reduces the amount of air entrainment, and concrete mixtures high in fly ash often require more air-entraining admixture.

4. Seasonal Restrictions

Now, the winter season is very problematic for concrete pouring, and mixtures high in fly ash are even more prone to low temperatures. As we highlighted before, low temperatures increase the setting times and cause slow strength gain even in concrete mixtures without fly ash. And, when fly ash is added it can exaggerate these problems.

5. Color Inconsistency

While the structural effects of fly ash in concrete are more critical, it also has some cosmetic concerns. If there is fly ash in concrete it becomes more difficult to control the color. Fly ash can also cause many more visual inconsistencies on the finished surface, like dark streaks rising due to carbon particles.

6. Size limitations

Fly Ash Bricks face major limitations in size. Also, only modular size bricks can be produced. Large size bricks face the danger of getting more breakages or cracks.

7. Restricted Suitability

Not all fly ash is suitable for construction, only those produced in power plants are usually compatible with concrete. Other fly ash may need beneficiation. It is very important to use only high-quality fly ash otherwise it can have negative effects on the structure.

Let’s Summarise

Smaller builders and housing contractors may not be very familiar with fly ash products, that can have different properties depending on where and how the fly ash was obtained. Also, fly ash applications can face resistance from traditional builders who are well aware of its tendency to effloresce along with the concerns about thaw/freeze performance. Other prominent concerns of using fly ash bricks include:

- Slower strength gain

- Seasonal limitation

- Increased need for air-entraining admixtures

- Increase of salt scaling produced by higher proportions of fly ash

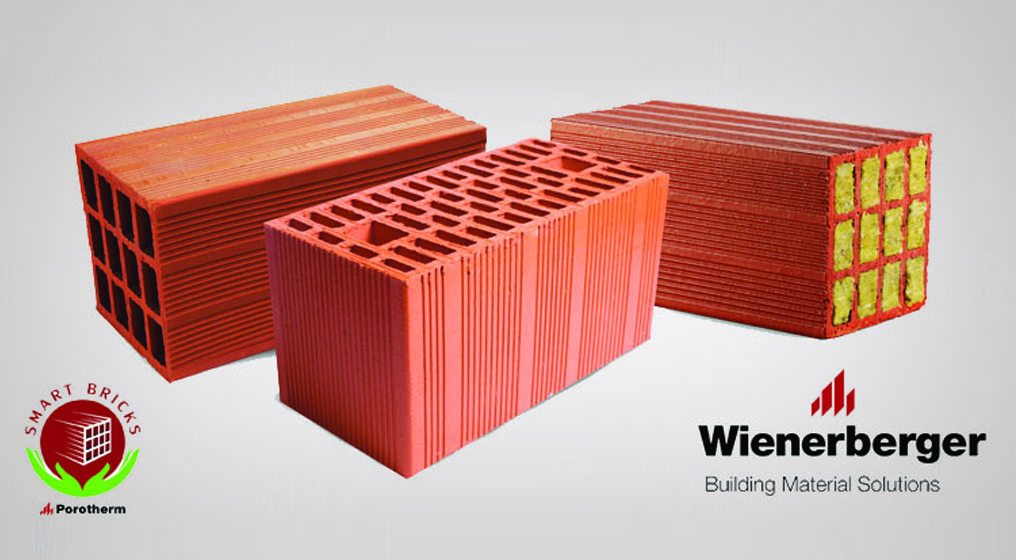

Alternatively, Walls made with Porotherm Smart Bricks i.e. has the power of Clay provides the home builders with a lifetime opportunity of building strong, comfortable, and healthy homes during all seasons.

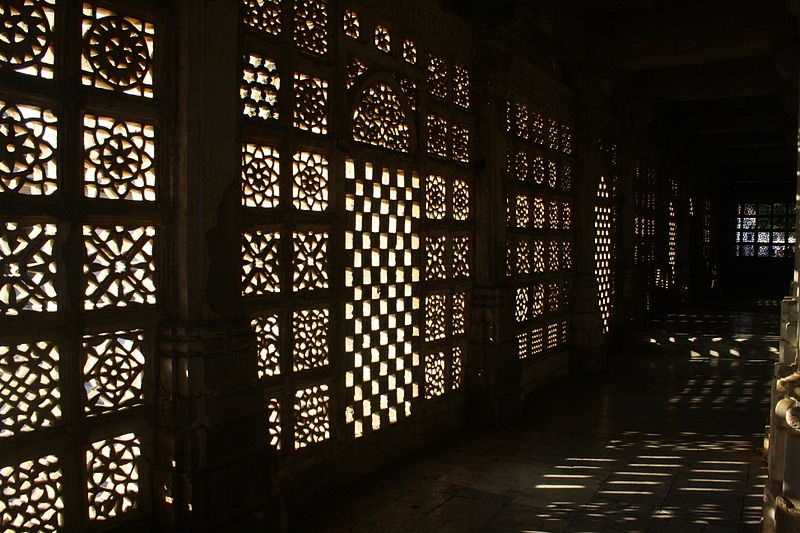

The perforated design of the brick ensures excellent thermal insulation that keeps indoor temperatures cool at all times. The best thing about the blocks is that they are entirely made of clay making Porotherm a Natural walling material, rated by the Green Building Council of India.

The perforated design of the brick ensures excellent thermal insulation that keeps indoor temperatures cool at all times. The best thing about the blocks is that they are entirely made of clay making Porotherm a Natural walling material, rated by the Green Building Council of India.

The large size of the blocks promotes savings in mortar consumption since one Porotherm 8″ block is equivalent in area to 9 small bricks. Another spectacular feature of Porotherm is the precision in design. The blocks are highly dimensionally tolerant making Porotherm a one-of-a-kind wall solution in the market. Also, Porotherm blocks are 60% light in weight than any other conventional walling block thus aiding in faster construction. Apart from all these, Porotherm blocks also have the lowest water absorption because of which possibility of superficial or shrinkage cracks on plaster is none…no wonder they are called POROTHERM SMART BRICKS!

Read more at www.wienerberger.com.

Featured Image by Praveenvatsa under CC BY-SA 4.0

http://co2frei.fh-ooe.at/17-cat/dating_32.html Curated by editor at Wienerberger India

i want to buy Clomiphene online uk Recommended Videos:

suturally Like this story? Or have something to share? Write to us: gosmartbricks@gmail.com or connect with us on Facebook and Twitter.