Evolution and change are two things that help any industry in keeping in stride with the fast-moving world. The construction industry has kept pace with all the technological advancements that have been introduced to make the process of construction efficient in terms of time and money. One such innovation is 3D printing which has revolutionized this industry.

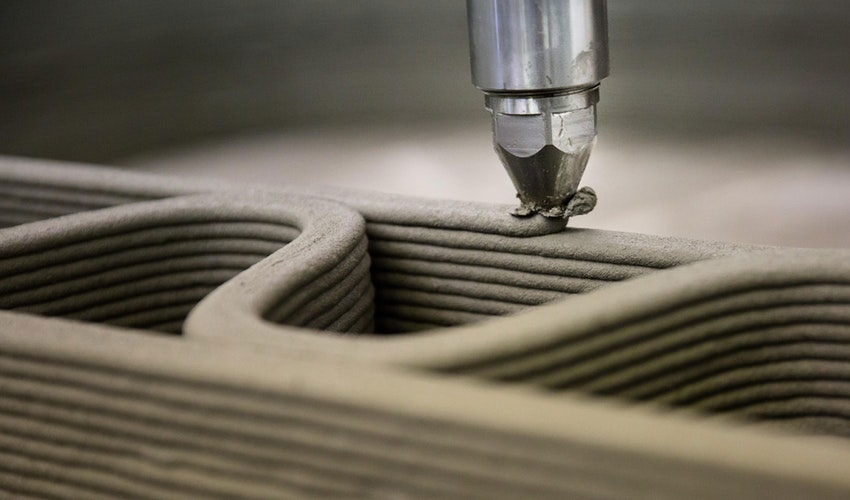

The first 3D printed wall was built in 2004 by Professor Behrokh Khoshnevis of the University of South Carolina and since then, this technology has come a long way. Now, 3D printing has grown so much that you can build a small house itself in one day! 3D printing is also known and Additive Manufacturing and it is basically a computer-controlled sequential layering of construction material to create three-dimensional shapes or a house in this case.

3D printing can be used not just to create separate components but it can also print an entire building. The construction industry has adapted well to this technology as the information needed for 3D printing which is the design/ blueprint is anyway being created using a computer-aided process.

3D printing development across the globe

Image Courtesy: 3dnatives.com

There is tremendous competition in the 3Dprinting market internationally. Various market players have developed machines that use the latest technologies to 3D print concrete. A polar 3Dprinter by French company Constructions-3D does the printing right at the construction site and then leaves through the front door of the building once construction is complete. This printer has a mechanical base along with a robotic arm with a nozzle for the material output at the end. With this arm, you can get a printable area of more than 250 m² and over 8 meters high.

While there are 3D printing machines that extrude only concrete, technologies are being developed to create printers that will extrude more than one material at a time. An industrial robot made in by the University of Nantes, Bouygues Construction, and Lafarge Holcim prints 3 layers of material at once; two of these layers being a polymeric foam, with the third layer being concrete.

Italian architect Enrico Dini is known to the world ‘the man who 3D prints houses’ and his ‘D-Shape’ 3D printer uses the binding of powder to solidify a layer of material with a binder. With this printer, large structures can be created easily.

It is not just concrete 3D printing that is making waves in the construction industry but also the printing of metal structure. A unique construction method called WAAM (Wire Arc Additive Manufacturing) developed by a Dutch company MX3D in collaboration with Air Liquide and Arcelor Mittal, can 3D print metal structures. This robot is like a soldering iron and has a welder and a nozzle that welds layer-by-layer metal rods using metals like bronze, stainless steel, aluminum, and Inconel.

How it is going to make the job easier

3D printing is an additive manufacturing process that lends more creativity, design flexibility, a lower carbon footprint, and sturdy structures. 3D printing allows faster and more accurate construction of geometrically complex designs. It also brings down the labor cost and reduces construction waste. 3D printing is also a viable construction option in harsh or dangerous environments that are not suitable for human labor. In a post-COVID world where social distancing is going to be a prevalent practice, this technology is going to be extensively used. Time plays a crucial role in the construction industry and since 3D printers don’t stop working until the project is finished, they reduce the project completion time. 3D printing concrete saves a lot of time and a 2-week job needs only 3-4 days for completion. With this technology, it is also possible to create curved shapes at a lower cost.

It’s still a long road ahead

The concrete 3D printing market is expected to reach $56.4m worldwide in 2021, but it is yet to become an integral part of the construction industry. One of the main problems it faces is that the process of 3D printing buildings has not yet been recognized as an approved construction method under many codes by construction standards bodies. Since it is not a traditional method of construction, the resistance calculation in time is still being done on a case by case basis. It is yet to be determined and proven if these structures can withstand time, weather, and environment. The foundation of 3D printing has been laid and it is time to now take this one brick at a time.