Mortar in construction occupies an important place as it is the most essential product for binding the stones and bricks of a building. There are various types of mortars available which are mainly segregated based on their binding strength, applications, bulk density, and binding materials. Some mortars are used for special purposes like providing fire- resistance, packing oil wells, reducing noise, protecting against the harmful effects of X-rays and resistance against a chemical attack.

It requires proper skill and knowledge of mortars to select the right one for any construction project. You must be aware of the structural design requirements before finalizing the type of mortar in construction. Inputs from different stakeholders in a construction project must be considered along with the effects of weather to select the correct and appropriate type of motor.

Types of Mortar In Construction

ASTM, the American Society for Testing and Materials, is an organization that mentions certain specifications and standards for materials to ensure durability and security. The ASTM C 270 divides mortar in construction into four different types based on their binding capacity, Type M Mortar, Type S Mortar, Type N Mortar, and Type O Mortar. Let’s know a little more details about them:

1. Type M Mortar

It possesses the greatest binding strength among all. The minimum compressive strength of Type M Mortar is 2500 psi. Its strength is almost equivalent to stone, hence recommended to be used in external places like driveways, retaining walls, springs and fountain areas, walls capable to bear a heavy load. It is not preferable to use Type M Mortar is areas that are exposed since it lacks in providing proper adhesion or sealing capabilities.

2. Type S Mortar

The binding strength of this type of mortar is medium. The minimum compressive strength of Type S Mortar is 1800 psi. It is recommended to be used for below-grade projects like in sewerage systems, pavements, pathways, exterior walls. It is capable to tolerate to bear pressures from an earthquake or similar vibrations due to pressure from soil or wind.

3. Type N Mortar

The binding strength of type n mortar is also medium. But its minimum compressive strength is lesser than of Type S Mortar, its 750 psi. It consists of a mixture of sand, lime and Portland cement in the proportions of 3, 1 and 1 respectively. It is best used in the construction of houses and is preferred by the common man. Type N mortar is also preferred in the construction of buildings or sculptures which use soft stone.

4. Type O Mortar

The binding strength of this mortar is low. The minimum compressive strength of Type O mortar is 350 psi. It is mostly used in interiors which has a low load-bearing capacity. Generally, this type of mortar is not used in exterior constructions and places where there are high wind pressures. Since it can be applied very easily it is perfect to be used for repairing any joints or any other repair work in an already established structure.

There is another type of mortar, http://uslanka.net/2019/02/15/ගයාන්-චතුරිකා Type K. It is seldom used in any buildings due to its low compressive strength, which is only 75 psi. Type K Mortar may be utilized for any building restoration work.

In addition to the standards and specifications mentioned by ASTM, mortars can also be subdivided based on the binding material. The categories can be :

- Cement Mortar which is water-resistant and strong

- Lime Mortar, used in areas which are subject to water clogging or dampness

- Gypsum Mortar, generally to be avoided in damp areas

- Gauged Mortar, similar to the lime mortar with more durability and strength due to the addition of cement to lime

- Burnt clay Mortar, which is strong and available at a low cost

- Mud Mortar, used as a substitute for lime mortar or cement mortar

The requirements of mortars for brickwork and that of any building with architectural significance are different. The second one should have the capability to withstand the resistance and pressure from various natural phenomena like rain, storms.

Certain structures necessitate a special purpose and demands preparing the mortar to satisfy the unique needs of the construction. For example resistance from fire, oil wells, soundproof, shielding X-rays and resistance from chemicals. The mortar constituents must be mixed in adequate proportions to meet the above specifications.

Guidelines for Selecting the Appropriate Mortar

The important and essential criteria for selecting the correct type of mortar is to first understand the two questions:

“Do your construction project demand high or low compressive and binding strength?”

“Is the mortar capable to protect the underlying brick or stone layer?”

It is compulsory to consult an engineer and be aware of the structural needs of your construction. Based on the specifications or requirements, the right proportion of the ingredients is mixed to derive the desired strength of the mortar. The key elements which are combined are lime, cement, and sand. The ratio in which they are fused determines their binding strength, enduring power, and flexibility. The compressive strength of the mortar must be robust enough to bear the structure. But the strength should be comparatively less than that of the surrounding brick or stone units.

The construction projects generally opt for two different methods to finalize the mix of the constituents required for preparing the exact type of mortar. One method is to experiment in a laboratory and test the performance of the mortar before applying it finally in the structures. The important factors which are considered in the experiment are the mix ratio of the elements and the percentage of water and air in the mortar. The second method is to directly mix the elements in appropriate ratios, after proper analysis and study, instead of experimenting.

http://ifcus.org/templates/beez3/cgialfa Tips:

For new constructions selecting the mortar is quite straightforward since the manufacturer ideally specifies the type of mortar to be used. The difficult part is choosing the mortar while restoring old or historical buildings or for any repair work. Proper attention and analysis are required for selecting the appropriate type of mortar.

Related: Top 10 Types Of Masonry In Indian Construction

Why Say ‘No’ To Wet Mortar

Presently the construction industry is plagued with numerous challenges; out of that pool, the most alarming one is the shortage of natural resources like water and sand. Bearing in mind the rapidly increasing volume of construction in the urban areas, saving water in the pre-construction stages can provide huge relief to the city’s water crisis.

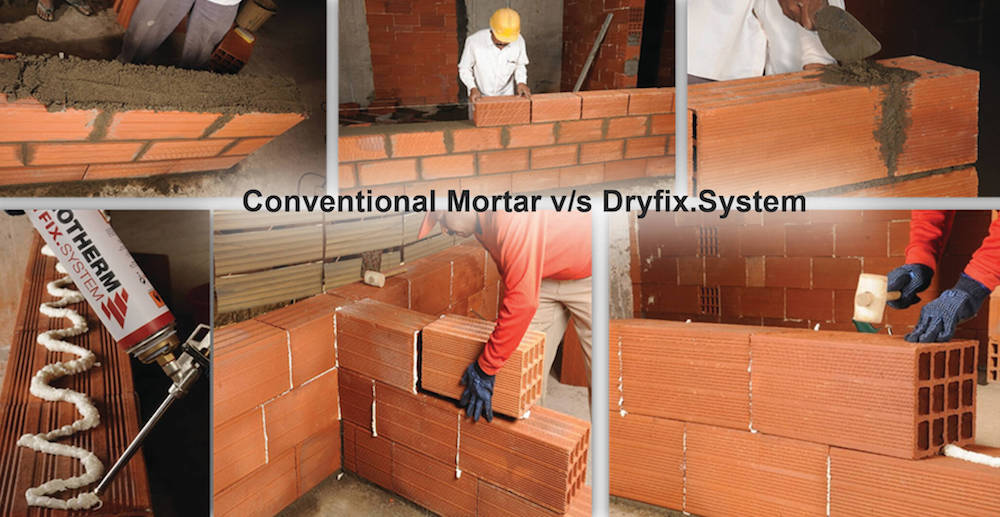

This is exactly where smart products like “Porotherm DryFix.System” from Wienerberger can play a huge role. This is a quick fix system that totally replaces the conventional masonry practices, resulting in dramatic water savings for any type of wall construction, i.e. infill masonry, partition walls or external walls. The system also eliminates the requirement for curing, consequently leading to water savings. Benefits of Porotherm Dryfix.System:

- Ready to use, mason friendly and easy to transport

- Fastest available masonry system

- Clean & dry construction – No Debris

- No need for chasing or curing

- Strong & reliable adhesive bond

- Zero site wastage

- Next construction activity can begin within 24 hours

- Enhances thermal protection

- Minimal water usage

- Improved quality construction

Dryfix.System is one total sustainable solution; it comes along with Smart Bricks or Porotherm Grinded clay hollow bricks. Since these bricks are a hallmark in precision technology it results in incomparable dimensional uniformity which reduces the thickness of the plaster leading to huge savings for the builder.

To know more about Dryfix visit Wienerberger.